Polyurethane Mouldings

DLR Elastomer can help you design, manufacture, and supply polyurethane products made to your exact requirements for a range of uses and industries. We have been manufacturing polyurethane and rubber products in our UK base site since 1895 and have become experts in the supply of bespoke polyurethane mouldings. Our PU mouldings are used in a wide range of uses and industries all over the world, from PU rings and seals to polyurethane coatings.

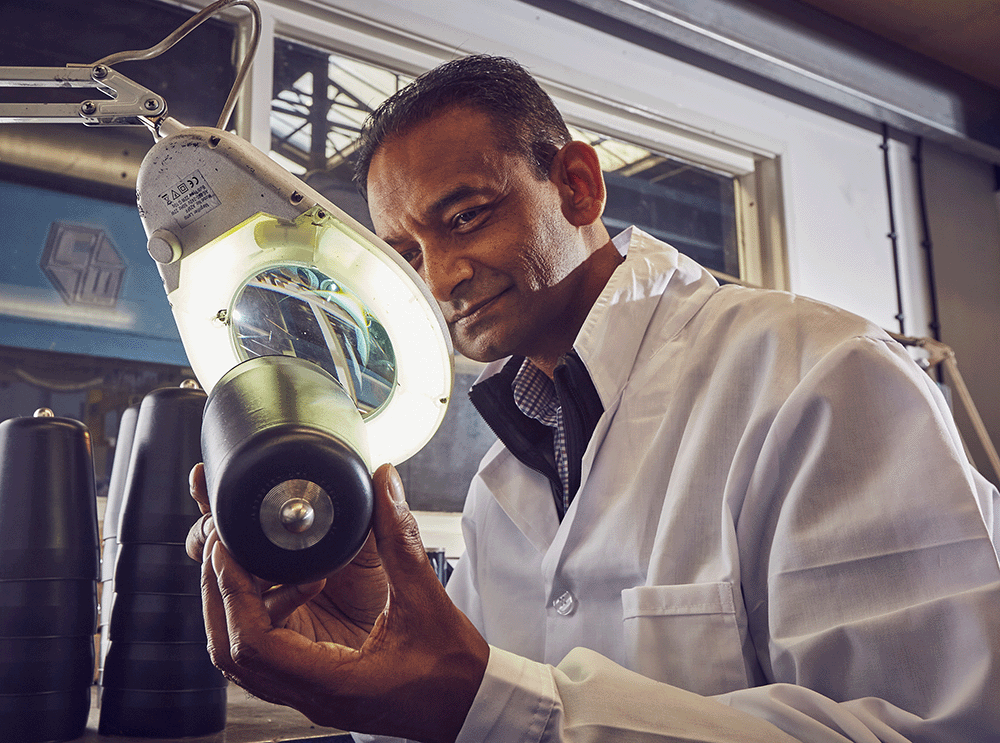

Our skilled technical team specialises in designing and developing custom polyurethane products. We collaborate closely with our customers to deliver high-quality and reliable solutions. From inception to completion, we offer a full project management service, ensuring your polyurethane product is delivered on time and meets your expectations at every stage.

Experts in PU Moulding

We have extensive experience in the design, development, prototyping and manufacture of cast polyurethane products for a wide range of uses. From our Leyland-based site, we supply our clients worldwide with a range of bespoke polyurethane mouldings for uses such as:

- Wheels and tyres

- Polyurethane coatings

- Polyurethane buffers

- PU rings and seals

- PU rods

- Polyurethane sheets

Custom Seals

We can cater for a wide-ranging set of industry partners from Aerospace and Automotive to defence and marine. Working with them on all their design and manufacture requirements, from door seals to custom rubber seals for use in harsh environments.

Custom SealsCustom O-Rings

DLR Elastomer Engineering is proud to offer a diverse range of O-rings crafted from durable elastomeric materials. These O-rings are engineered to deliver exceptional sealing performance in various automotive, aerospace, and industrial settings.

Custom O-RingsCustom Fluid Seals

We specialise in designing and manufacturing high-performance fluid seals and wear parts for some of the most challenging and demanding environments. We can help design and manufacture rubber hydraulic seals, piston seals, rod seals, wiper seals and wear rings.

Custom Fluid SealsWant To Know More About Our Polyurethane Moulding Services?

Discover the versatility and quality of our custom polyurethane products and mouldings! Whether you need durable seals, precision components, or bespoke anti-vibration mounts, we’ve got you covered. Benefit from our expert material selection, advanced polyurethane-to-metal bonding, and in-house manufacturing capabilities. Perfect for a variety of industrial and commercial applications, our polyurethane components are designed to meet your specific needs.

Get in touch today to find out how our tailored polyurethane solutions can enhance your projects. Contact us now and speak to our expert team.

FAQs for Polyurethane Casting & Moulding

Polyurethane (PU) is a versatile polymer that combines the rigidity of plastics with the elasticity of rubbers. It is used in a variety of applications due to its durability, abrasion resistance, and ability to be formulated in a wide range of hardnesses and colours.

Polyurethane can be categorised into two main types: polyester-based (AU) and polyether-based (EU). Polyester PUs are generally more durable, while polyether PUs offer better resistance to water and humidity.

Polyurethane mouldings are used in a wide range of applications, including abrasion-resistant coatings, gaskets, haul-off pads, hoses, seals, and moulded diaphragms. They are particularly valued in the automotive, aerospace, and oil and gas industries.

Yes, polyurethane mouldings can be used outdoors. They are highly resistant to weather conditions, including exposure to sunlight, ozone, and a wide range of temperatures.

Polyurethane offers high abrasion resistance, good tensile strength, excellent tear resistance, and chemical resistance to petroleum-based fuels and oils. It also has good electrical insulating properties, making it suitable for a variety of industrial applications.

Polyurethane is less resistant to strong acids, alkalis, and some solvents. Polyester-based PUs can be affected by hot water and high humidity, making them less suitable for such environments. Additionally, they may not be ideal for applications requiring high compression set resistance.

Polyurethane mouldings typically perform well in temperatures ranging from -40°C to +90°C, with some formulations able to handle short-term exposures up to 120°C.

Yes, polyurethane can be easily coloured during the casting process. This allows for customisation to meet specific aesthetic and functional requirements.

Any questions? Get in touch

Since 1895 DLR has been combining expansive knowledge of materials, their properties, and processing techniques to develop bespoke mouldings and fabrications for many industry sectors. Our core services include moulding rubber, rubber sheeting, Petroseals, and cast polyurethane products. If you have any questions about our products, our process or the materials we use get in touch today!