Is Polyurethane a Plastic?

Is Polyurethane a Plastic?

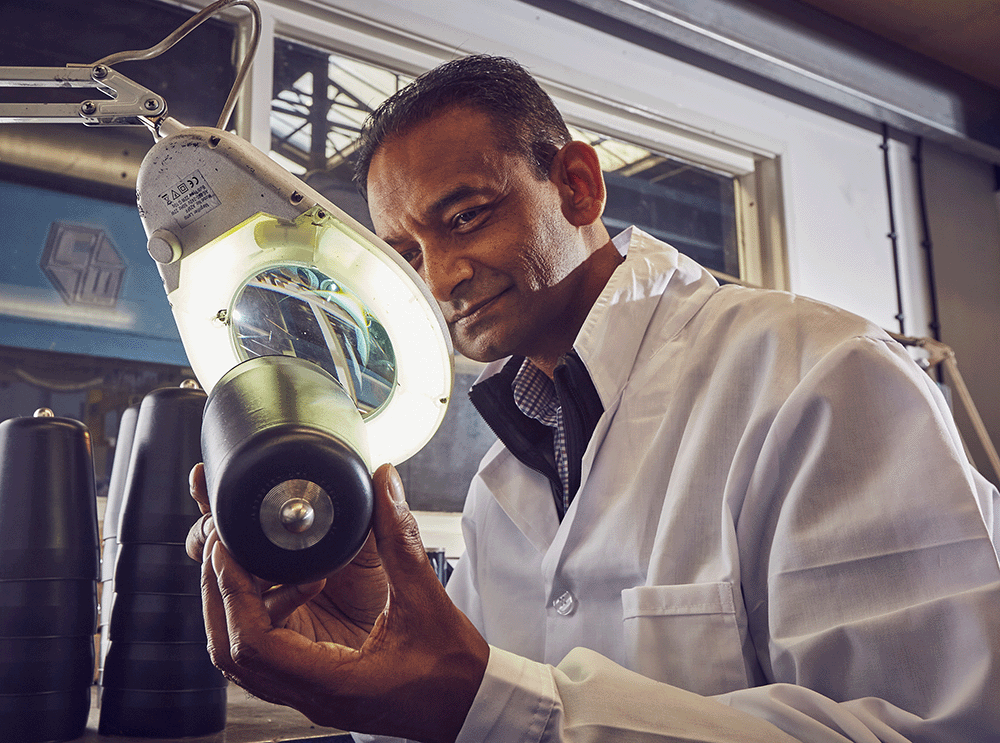

Polyurethane (PU) is a unique polymer that is elastic like a rubber but can be repeatedly stretched and reformed like a plastic. This tough, flexible and hard wearing material can be formulated using a wide range of starting materials to develop everything from paint to car parts, shoe soles and seals. So is Polyurethane a plastic? DLR Elastomer Engineering explains.

What is Polyurethane (PU)?

So what is Polyurethane and is it a plastic?

Polyurethanes (PU) are polymers (materials made of long, repeating chains of molecules) with a versatile chemistry that produce materials that behave like plastics and rubbers. PUs are made by reacting a polyol, which is an alcohol with more than two reactive hydroxyl groups per molecule, with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. The end result is a polymer boasting outstanding tensile strength combined with excellent tear and abrasion resistance.

It is the wide range of starting materials that can be used that ensures PUs exhibit both plastic and rubber characteristics. There are PUs that are rubbery and elastic, which can be melted and formed into parts and the cycle repeated! This means that Polyurethane products can be developed using cost-effective, sustainable Polyurethane casting and moulding techniques. Both of which are desirable outcomes for the modern manufacturer.

PUs come in a wide range of hardnesses using just two or three chemicals combined in a smart way. These materials are tough, flexible and hard wearing. Parts manufactured using a PU can be coloured and finished off to high gloss levels. They can also be manufactured to include inserts, such as metal fixings, other polymers, or PUs of different hardnesses. The advantages of Polyurethane don’t stop there either.

Advantages of Polyurethane

Thanks in no small part to their high degree of durability and excellent resistance to oxidation, ozone and petroleum-based fuels and oils, PUs are extremely versatile materials. The fact that they can be formulated to be either rigid or flexible makes them suitable for a wide range of applications. For instance, Polyurethane is a particularly good choice for custom moulded products intended for oil and gas applications.

Polyurethane also exhibits good electrical properties, which makes it especially useful as a coating to protect electrical products. It is commonly used to insulate buildings and white goods, such as refrigerators and freezers. In fact, a 1.6cm thick Polyurethane sheet of insulation delivers the same insulation as a 1.34m thick concrete wall! As PUs are typically liquid cast, tooling prices also tend to be lower than for heat and pressure moulded elastomers.

Applications of Polyurethane

Cast PU is used in a vast array of applications, including the following:

- Abrasion-resistant coatings

- Moulded diaphragms

- Gaskets

- Haul-off pads

- Hoses

- Seals

Looking for more detailed information on the different types of rubbers and polymers we work with? Then check out our material guides where you can find FAQ’s and more guides like this one detailing all you need to know. If you are looking for rubber or polymer products get in touch with DLR Elastomer today via our contact page or via LinkedIn and we can chat over your requirements.

Any questions? Get in touch

Since 1895 DLR has been combining expansive knowledge of materials, their properties, and processing techniques to develop bespoke mouldings and fabrications for many industry sectors. Our core services include moulding rubber, rubber sheeting, Petroseals, and cast polyurethane products. If you have any questions about our products, our process or the materials we use get in touch today!